In the assembly workshop, every fitter adheres to the "ingenuity spirit" and strives for perfection in every part and every process. They know that the assembly accuracy of the mold directly affects the quality and production efficiency of the parts.

From the precise docking and gap adjustment of mold parts to the smooth operation of the guiding mechanism and the firmness and reliability of the locking device, every detail has been repeatedly verified and carefully debugged.

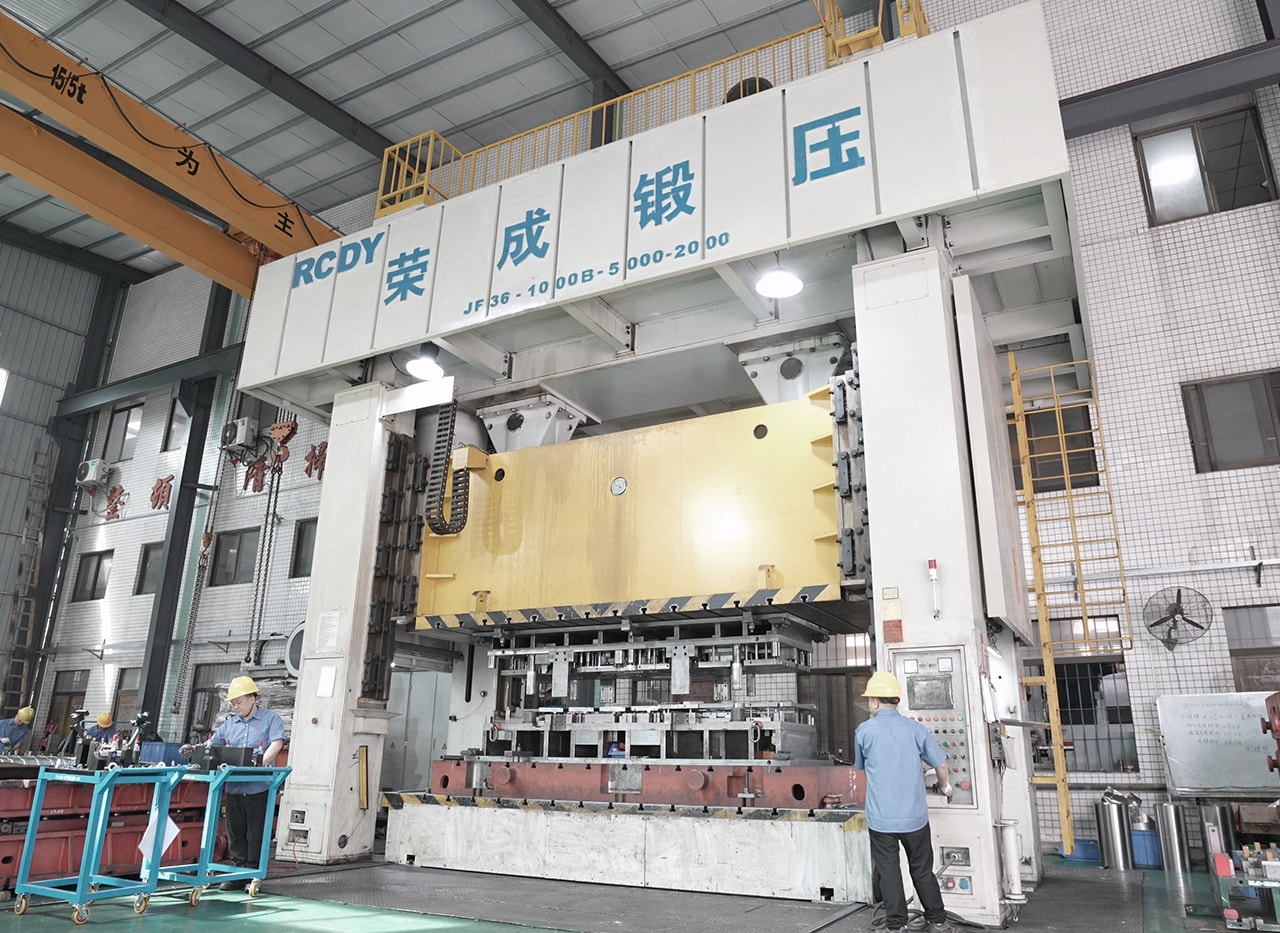

We are equipped with 1000T, 800T, 315T and other multi-specification stamping equipment, which can meet the needs of automobile hardware mold processing and mold testing of different sizes and complexity.

Use high-end manufacturing equipment in the manufacturing process and control production through ERP management system. Combine outstanding expertise and experience in industrial, automation, process, and software design data analysis to achieve seamless integration of software and hardware and provide comprehensive services.

Quality is the lifeline of an enterprise, and strict product quality inspection and perfect quality management system are the core barriers to guard this lifeline.

Chuang Ideal always regards "zero defect" as the ultimate goal of quality pursuit. Through the construction of a detection network covering the whole process and a refined management system, the accuracy, stability and reliability of each set of molds are escorted.