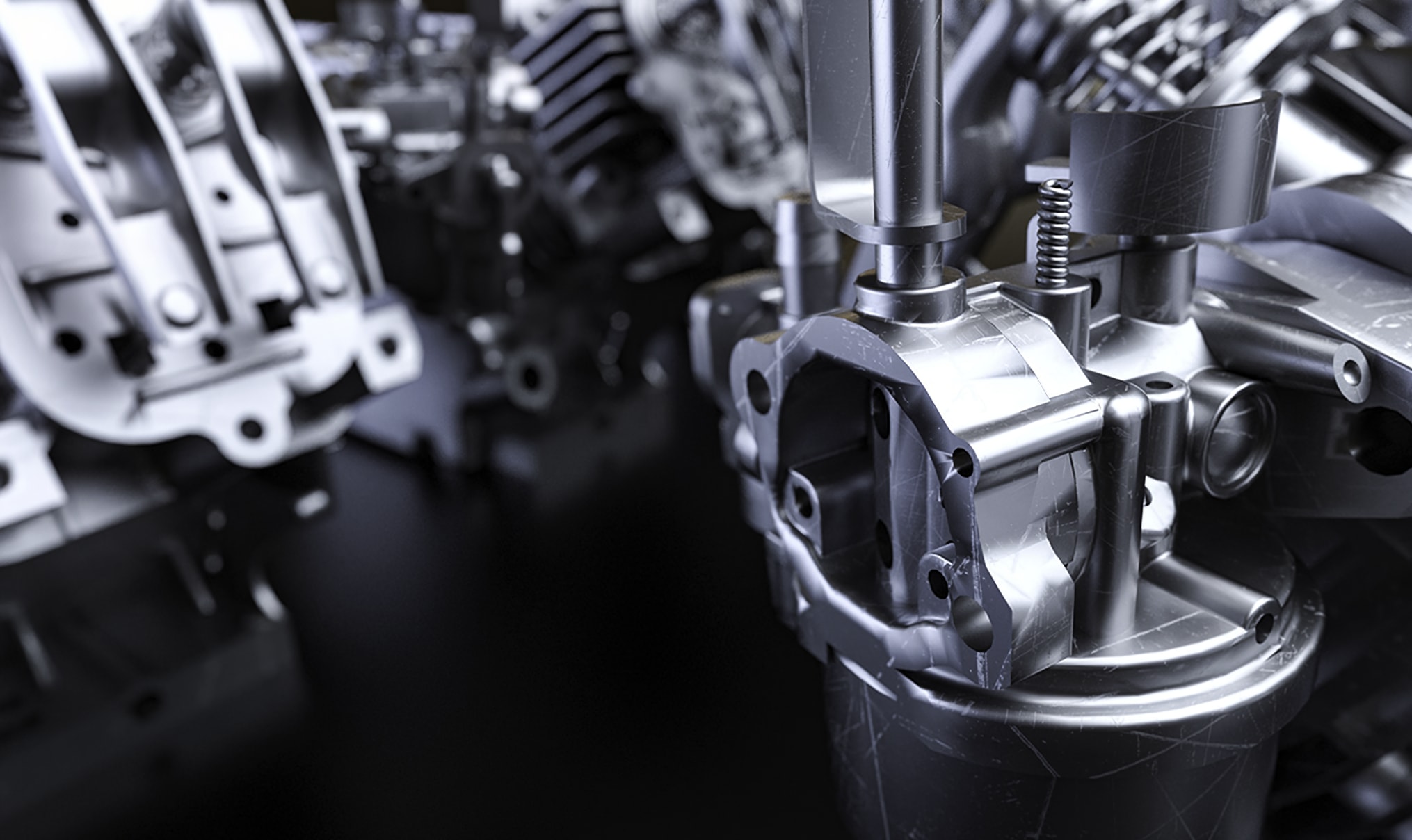

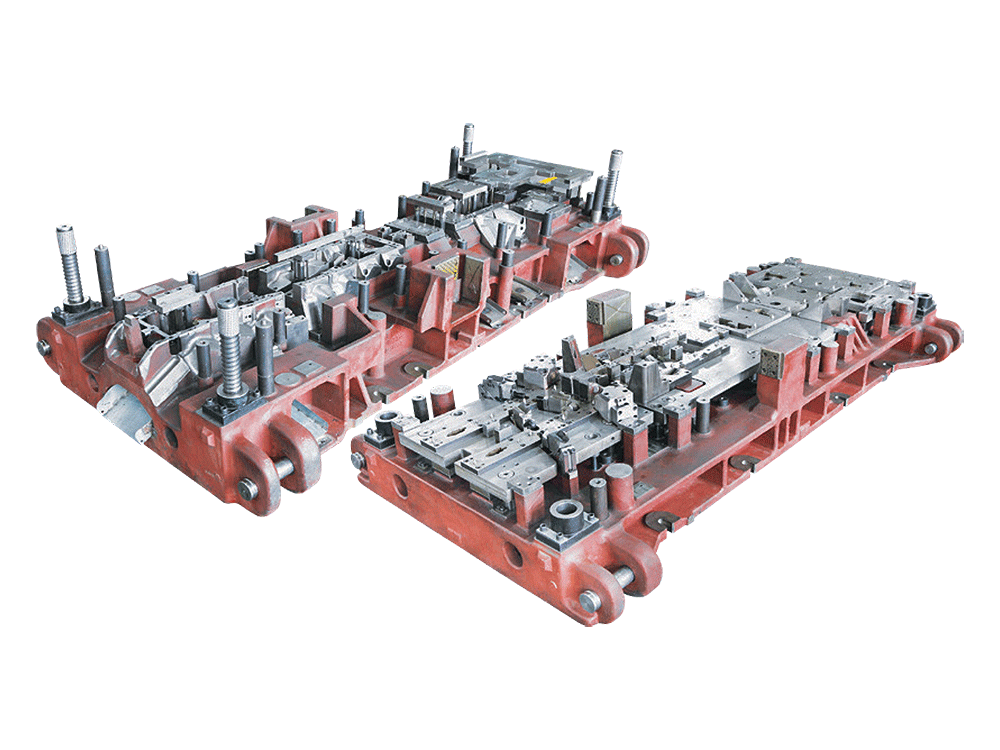

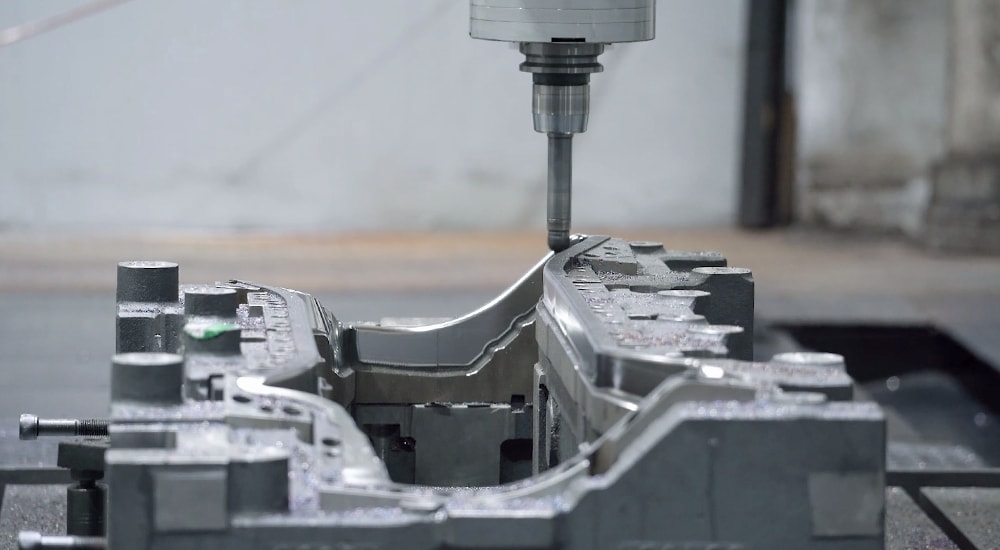

Multiple CNC automatic machining center, 24 hours of continuous processing operations, and equipped with wire cutting/milling machine grinding machine/rocker drill and other processing equipment

We believe that the continuous strengthening of hardware strength will provide customers with more reliable, efficient and high-precision mold products.

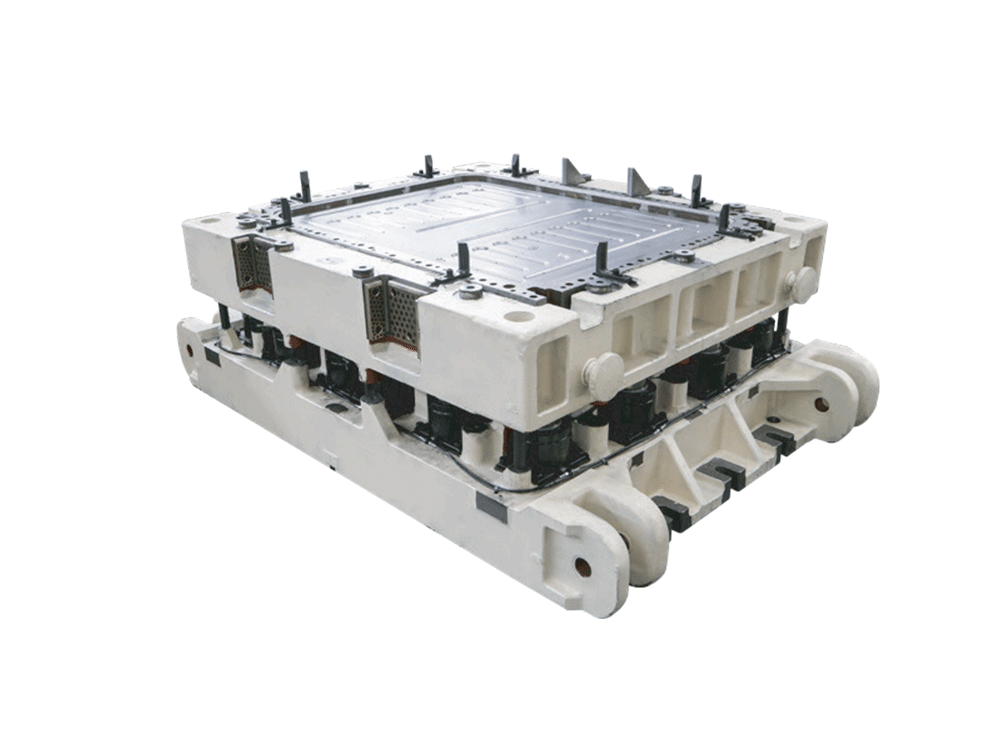

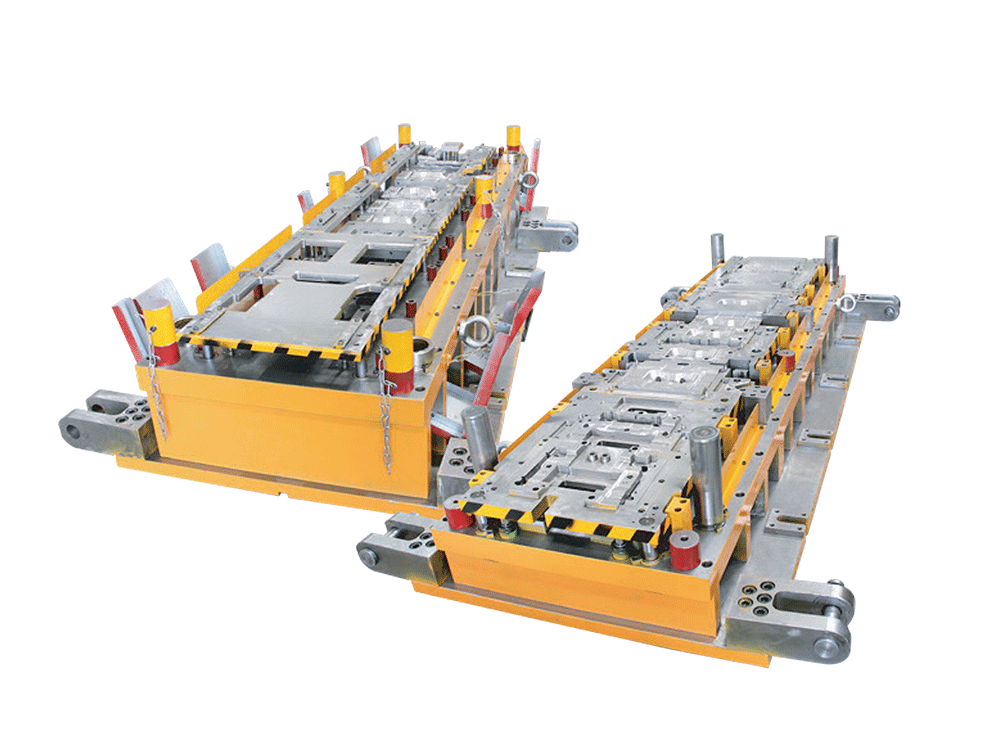

And a skilled assembly team to create reliable mold solutions for global automotive manufacturers.

-

Technical experience

Decades of industry experience, senior engineer. Combined with advanced production equipment, complete production line and perfect process flow, we can provide one-stop solution for mold design and production.

1 -

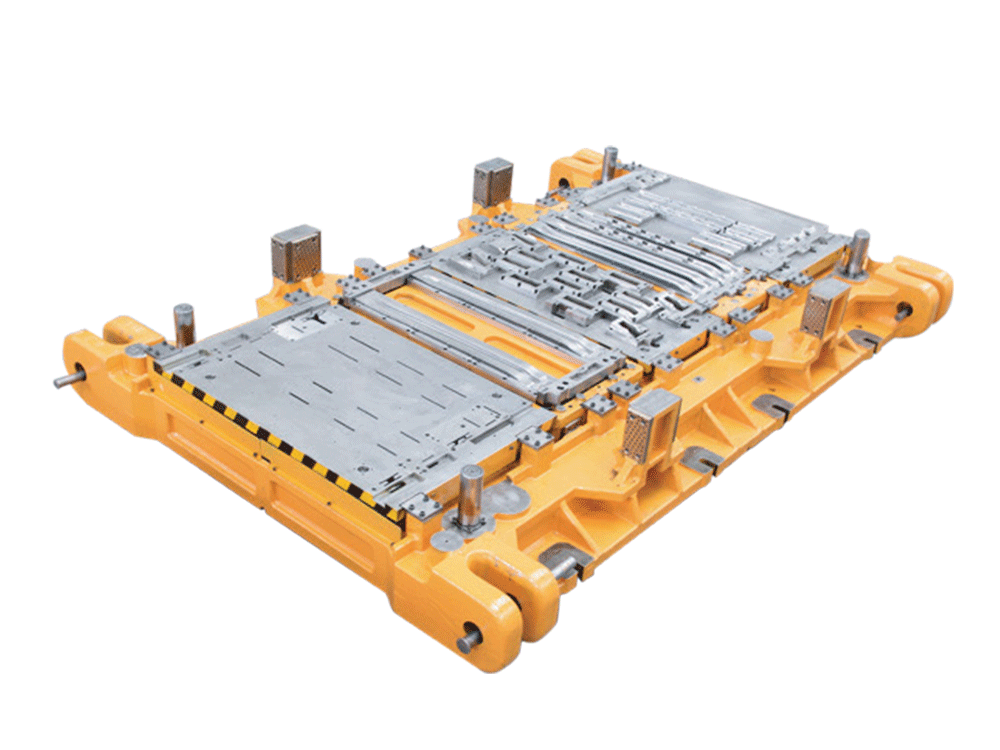

exquisite workmanship

The positioning accuracy is ± 0.003mm and the repeated positioning accuracy is ± 0.002mm. With the imported tool system, the surface roughness processing below Ra0.8μm can be realized, which meets the strict requirements of cutting edge sharpness and profile finish of automobile safety parts molds.

2 -

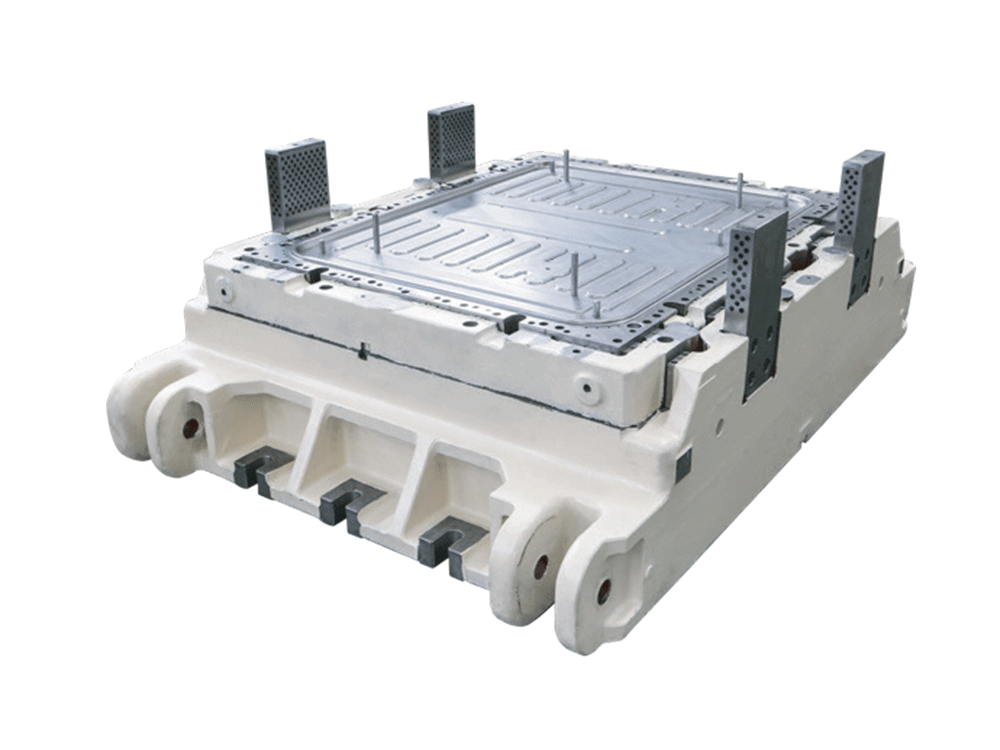

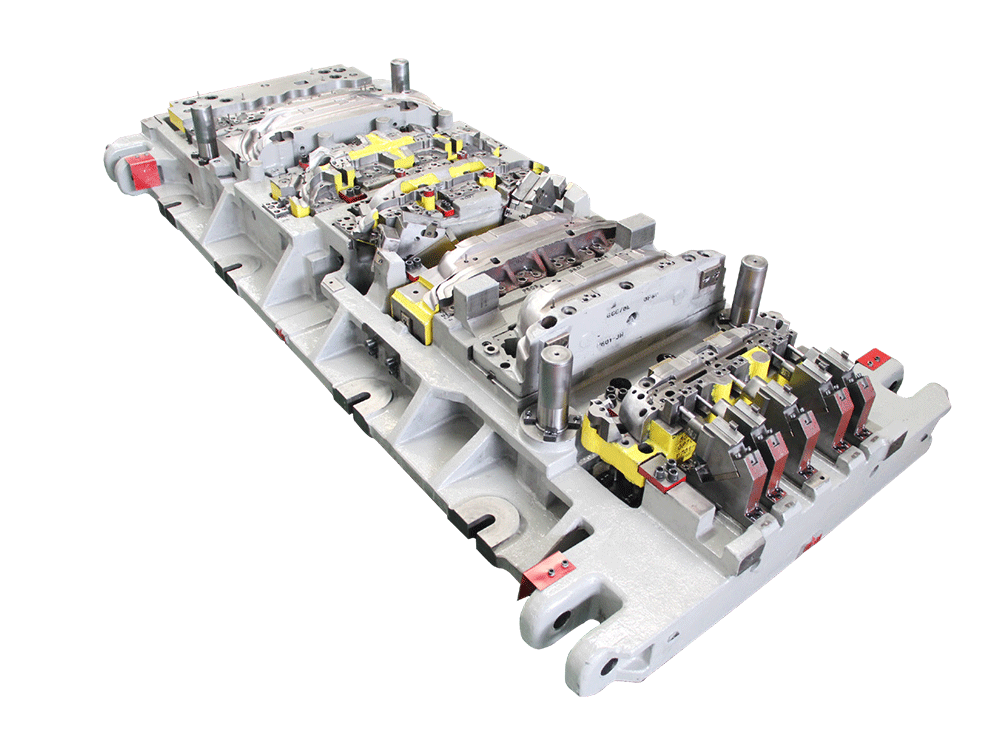

Quality Control

We have an experienced quality inspection team to test the quality of the products and check the quality of the products layer by layer. From production to shipment, we need to go through multiple full inspection processes to ensure that there is no error in the factory.

3 -

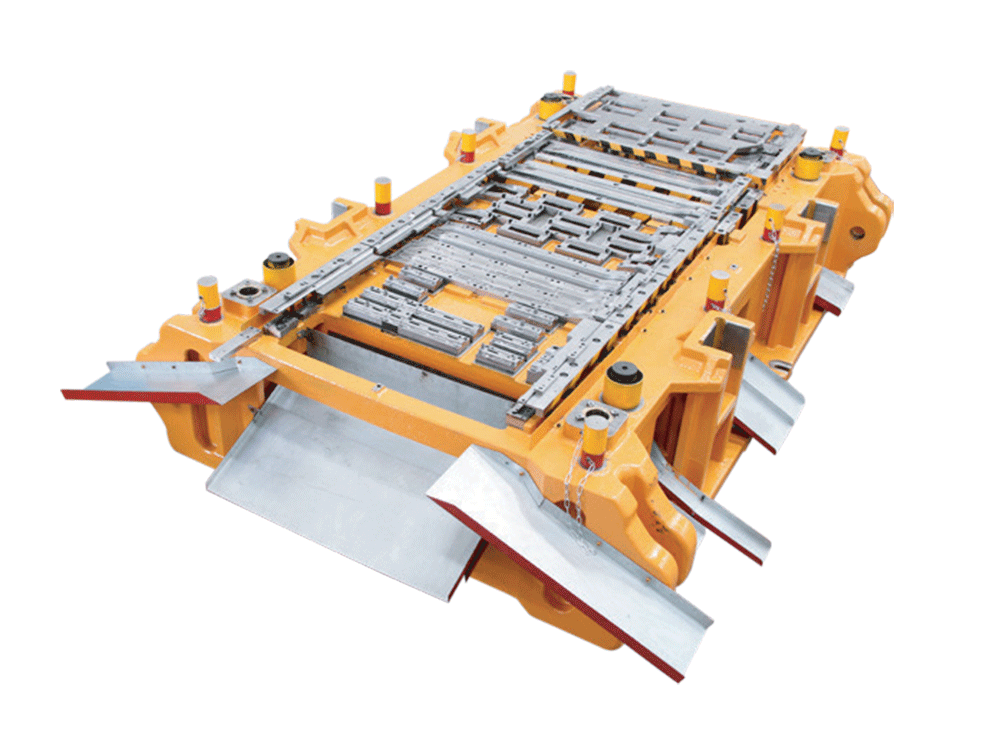

Ability to deliver

Our engineering design team participates in the customer's mold design and development throughout the process, assists the customer to quickly confirm the completion of the design structure diagram, gives suggestions for optimizing the product structure and improving the product structure, and effectively controls the time and capital cost.

4 -

Quality service

Professional service level team to create a perfect service system, one-to-one customer service, the whole process for customers to think, considerate and thoughtful, customer satisfaction is the proof that our efforts have been rewarded.

5

Participate in the customer's mold design and development throughout the process, assist the customer to quickly confirm the completion of the design structure diagram, give suggestions for optimizing the product structure, and effectively control the time and capital cost.