In recent years, the natural resources such as iron ore and coke required for the production of automobile steel are becoming increasingly tense. Improving the utilization rate of materials can not only reduce the manufacturing cost of automobiles and improve the competitiveness of automobile brands, but also conform to the environmental protection concept of energy saving and consumption reduction.

process optimization

Optimized blanking layout to reduce waste

For some special-shaped stamping parts, the arrangement of blank sheets in the uncoiling blanking die can be optimized to reduce waste, uncoiling as much as possible out of blank sheets and improve material utilization.

Fig. 1 shows the layout optimization of blank plates in the blanking die of the left and right inner longitudinal beams of the T6 model. the original one-step output plate is optimized to two-step output plate, which reduces the weight of scrap and increases the material utilization rate of the left and right inner longitudinal beams from 78.2 percent to 87.6 percent.

Consolidation of material specifications to reduce waste

In order to improve market competitiveness and enrich the sales product front, automobile factories will invest in new models every year, and new specifications and materials will be produced for new model parts. When the mass production of the model is over, the corresponding special steel will take up inventory due to slow consumption, so each addition of a new specification of steel will cause an increase in inventory and management costs, the car factory must ensure the versatility of steel as much as possible, reduce the number of steel varieties.

Since the uncoiling step distance of T6 hood is similar to the material width of X7 hood roll material, through on-site verification, the roll material of X7 hood can be used to produce the plate material of T6 hood with arc pendulum shear according to the parameter of step distance of 1170mm.

Through process optimization, the material utilization rate is increased by 3.7, and the steel specifications for the original T6 hood outer panel are reduced, which increases the versatility of the material and reduces the inventory and management costs.

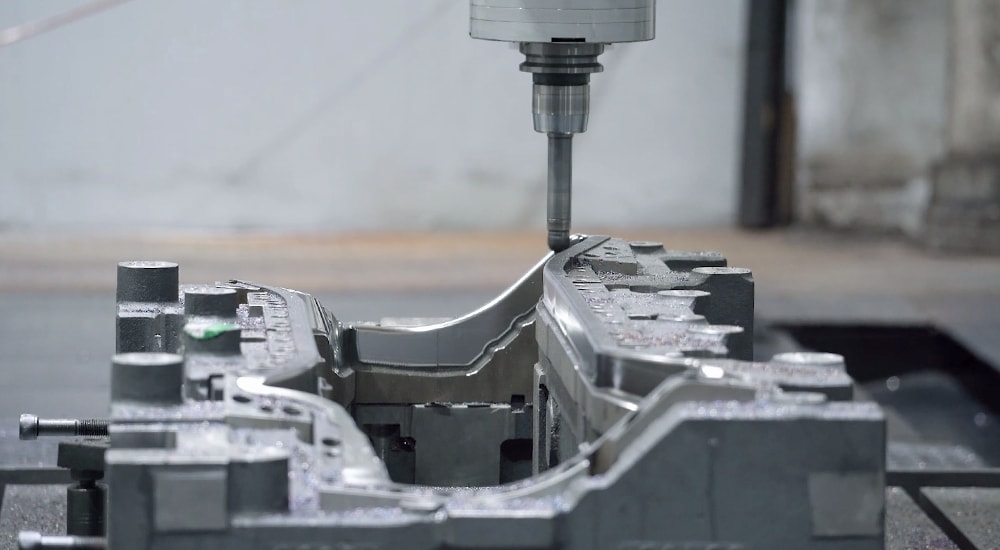

Mold design optimization, multiple parts in one mold

When multiple parts are produced on a set of molds at the same time, one or more small parts are produced by using the waste at the holes of the large parts to achieve the effect of improving material utilization.

For the B5 model hood inner panel and T7 door inner panel molds (Fig. 3), the hood reinforcement plate parts and the door lock reinforcement plate are stamped out by using the waste materials at the holes of the hood inner panel and door inner panel parts respectively, avoiding the need to use separate materials to produce the hood reinforcement plate and the door lock reinforcement plate.

Die Design Optimization, Slab Combination

In the mold design, the left and right symmetrical parts are designed to be stamped together. Through process optimization, two parts are stamped from two sheets of sheet metal to two parts are stamped from one sheet metal, which reduces the process supplement area and improves the material utilization rate.

Fig. 4 is a comparison between the mold design of the left and right rear door outer panel parts of MX3 model and the mold design of the left and right rear door outer panel of M44 model. The left and right rear door outer panels of the MX3 model are stamped with one part from one sheet, and the four directions of the parts require process supplementary surfaces; while the left and right rear door outer panels of the M44 model are stamped with two parts from one sheet, which is equivalent to reducing one process supplementary surface. By comparison, the material utilization rate of the M44 rear door outer door is 4.16 higher than that of the MX3 rear door outer door.

Material size optimization to reduce blank size

By adjusting the positioning of the blank sheet in the drawing die, the process supplement of excess material other than the drawing bead is reduced, thereby reducing the size of the blank sheet required for the part and improving the utilization rate of the material.

Fig. 5 shows the lower beam part of the front windshield of T/B model. observing the drawing forming transition part, it is found that a large part of blank sheet metal is not effectively used in the process supplement area of the drawing part. through measurement, the uncoiling step distance of this part is reduced from 590mm to 560mm, the drawing die is grinded, the sheet metal positioning device is adjusted, and it is confirmed after appearance inspection and three-coordinate measurement of geometric dimensions: when the step distance of the sheet metal is reduced by 30mm, the forming of the parts is normal and the quality meets the standard.

Control roll tolerance, increase the number of blanks

When steel mills produce steel coils and steel plates, they have a certain control range for the thickness tolerance of the product. Table 1 is the coil size control standard. If the thickness of the steel coil is delivered to the automobile factory according to the positive tolerance, the thickness of the uncoiled blank sheet will be too thick within the qualified range, which will cause the actual weight of the blank sheet and stamping parts to be higher than the process quota weight. On the other hand, the actual sheet quantity of the uncoiled steel coil will be less than the theoretical quantity, resulting in a decrease in the yield.

For example, R33 top cover parts, the blank sheet metal specification is 0.8mm × 1150mm × 1680mm, and the material grade is DX54D Z. There are three suppliers of materials, and the tolerance dimensions of the materials of the three suppliers are within the qualified range. However, through tracking, the actual sheet metal quantity of one material after each uncoiling is less than the theoretical quantity, while the actual sheet metal quantity of the other two steel coil materials after uncoiling is slightly higher than the theoretical quantity.

The process consumption quota of R33 top cover parts is 11.993kg. A 10t steel coil can theoretically uncoil R33 roof sheets with 10000kg/11.993kg = 834 sheets. According to the standard in Table 1, the yield strength of DX54D + Z material used for R33 top cover parts is less than 280MPa, and the coil width is 1150mm and less than 1200mm. Therefore, the thickness difference between the thinnest and thickest sheets is 0.06mm, and the maximum and minimum number of sheets that can be uncoiled for a 10t steel coil are 996 and 771 respectively, with a difference of 125 sheets. Under the condition of negative tolerance delivery, compared with the positive tolerance delivery, the material utilization rate is increased by 15%. Therefore, steel mills are required to adopt negative tolerance delivery for steel coils, which can significantly increase the number of blanks and improve material utilization.

Waste collection and reuse

When some parts are uncoiling and blanking, a large area of unused waste will be generated. Using these waste materials for the production of other small parts on the car body can avoid the separate purchase of materials for small parts, save costs, and improve The material utilization rate of the whole vehicle is improved.

Fig. 6 shows R33 rear fender inner panel sheet material, the coil material specification is 0.7mm × 1275mm, and there is waste material during uncoiling. The plate size of the front wall upper cover plate part is 0.7mm × 445mm × 1070mm, and the consumption quota is 2.594kg. The material grades of the two parts are the same. By collecting the waste material from the uncoiling step of R33 rear fender plate and using it to produce the front wall upper cover plate part, the material utilization rate is increased by 13%.

The scrap of R33 side wall outer plate is collected by similar method, and the coil size is 0.85mm × 1450mm, and the material grade is DX56D Z. The front parts of the left and right rear wheel housings of R33 are 0.8mm × 930mm × 254mm in size and DX56D Z in material grade.

By collecting the waste generated during the uncoiling of the R33 side wall and manually trimming the waste, the obtained rectangular sheet can be used to produce the R33 left and right rear wheel cover parts, and the material utilization rate is increased by 8%.

High roll weight, reduce head and tail waste

The stamping process is that the material supplier supplies the packaged roll material, which is unpacked and cut into various shapes of sheet metal required for stamping by uncoiling equipment, and then various parts are stamped out. When uncoiling, the outer ring and inner ring of the coil need to be cut. At the same time, the head and tail of the coil need to pass through the uncoiling equipment. The head and tail of each roll of material are about 15 meters for normal production loss. Therefore, the larger the uncoiling batch, the heavier the average weight of the coil material, the higher the uncoiling efficiency, and the less the average loss of the coil material.

The overall side wall outer plate material of a certain vehicle consumes about 60kg per vehicle. The stamping uncoiling line has a large batch, tracking the roll weight of its side wall material. The roll weight distribution range is 7t to 15t, with an average weight of about 10t. After calculation and analysis, if the roll weight is increased to 18 t, the uncoiling line will produce one less roll per batch, I .e. one less roll head and tail treatment, and the utilization rate of side wall material can be increased by about 1%, uncoiling efficiency increased by about 5%. According to the equipment capacity and transportation conditions, the coil weight requirement is put forward to the steel mill. At present, the average coil weight of this side wall material is 18.5t, and the utilization rate of coil material converted into sheet material is increased from 98.2 to 99.2 (sheet material conversion rate = net weight of coil material/consumption quota × 100%).

Conclusion

For stamping parts, the material utilization rate of the same part reflects the level of process and technology. There are many methods to improve the material utilization rate, and more methods need to be verified by practice. For example, when stamping parts are blanking, the existing linear knife or arc knife is changed to wave knife. By changing the shape of the slab, the length of the slab is shortened, thereby improving the material utilization rate, this method needs to account for the investment of the mold, the maintenance cost and the income relationship after improving the material utilization rate. In short, improving material utilization is to reduce the full cost of the vehicle, in doing to improve material utilization program needs to be combined with vehicle output, consider the relationship between investment costs and benefits.