Blu-ray scanning technology is currently a relatively mature technology, which is widely used in the automobile manufacturing industry. The equipment is mainly used for casting blank inspection in automobile mold factory, and is mainly used for quality control of parts in automobile main engine factory.

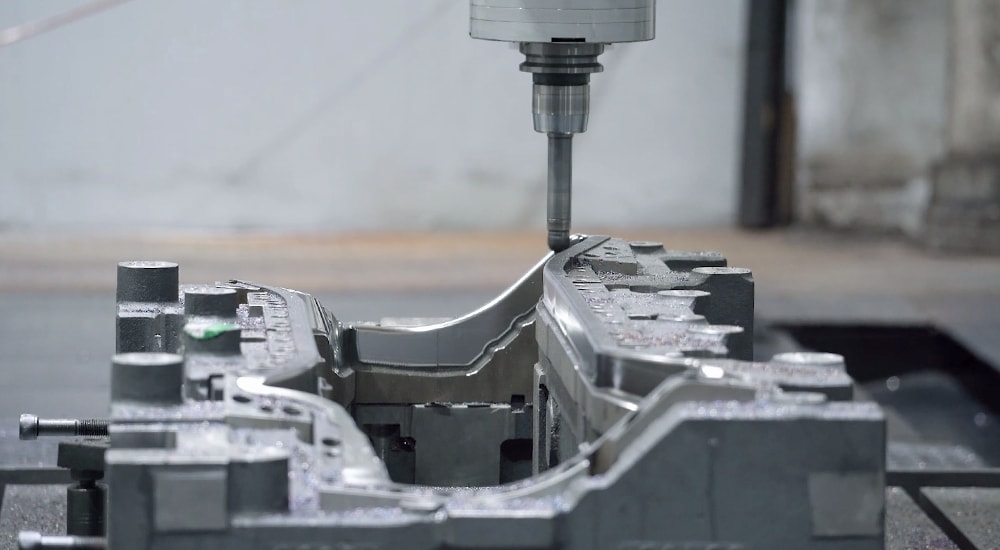

In the automobile main engine factory, the stamping die has always been the core of the stamping factory. Maintaining the die and making it continuously and stably produce qualified parts is the main task of the stamping process technology team. With the rapid development of related technologies around the mold, the daily maintenance of the mold is gradually changing from the traditional manual maintenance based on fitter to the mechanized maintenance based on numerical control technology.

BBAC, as an automobile OEM, introduced a 3 2-axis gantry milling machine in 2017 in order to improve the quality of daily mold maintenance. After that, the equipment played an important role in assisting mold maintenance. However, in the process of use, we also found a very difficult problem, that is, the processing data of the mold does not match the real object. Because the action of the CNC machine tool is completely driven by the processing data, the problem of the mismatch between the processing data and the physical object greatly limits the application range of the CNC machine tool. Through analysis, we found that the main reason for the data mismatch is: after the mold is processed in the mold factory, it needs to go through many manual optimization and debugging to reach the delivery standard, but this manual change cannot be synchronized and fed back to the existing processing data, which finally causes the data mismatch problem. At the same time, unfortunately limited by the existing production and manufacturing processes and conditions, such manual changes at the delivery stage cannot be completely circumvented.

In response to the above problems, in order to further increase the proportion of CNC equipment involved in the daily maintenance of molds, improve the quality of mold maintenance, and solve the problem of data mismatch, BBAC introduced GOM Blu-ray scanning equipment in 2018. This paper mainly focuses on the application of blue light scanning technology in mold maintenance.

GOM Blu-ray Scanning Device Introduction

Basic Principles

BBAC uses GOM's ATOS II TRIPLE SCAN. The ATOS measurement system is based on the principle of triangulation and extracts each measurement point into a quasi-triangulation measurement. During measurement, the ATOS measurement head projects stripes to the place on the object where both cameras can capture, and the camera can generate up to 16 million high-precision three-dimensional points per measurement.

In addition, the equipment is equipped with a projection head and a total of two left and right cameras, as shown in Figure 1; Through system calibration, the software knows the angular relationship between the left and right cameras and the projection head in advance, and through fringe projection, as shown in Figure 2; As long as there is an area seen by one of the cameras, the graphic information acquisition can be completed. The principle of triple scanning is shown in Figure 3. This function greatly improves the scanning efficiency of the concave area.