Idea Tool and Die

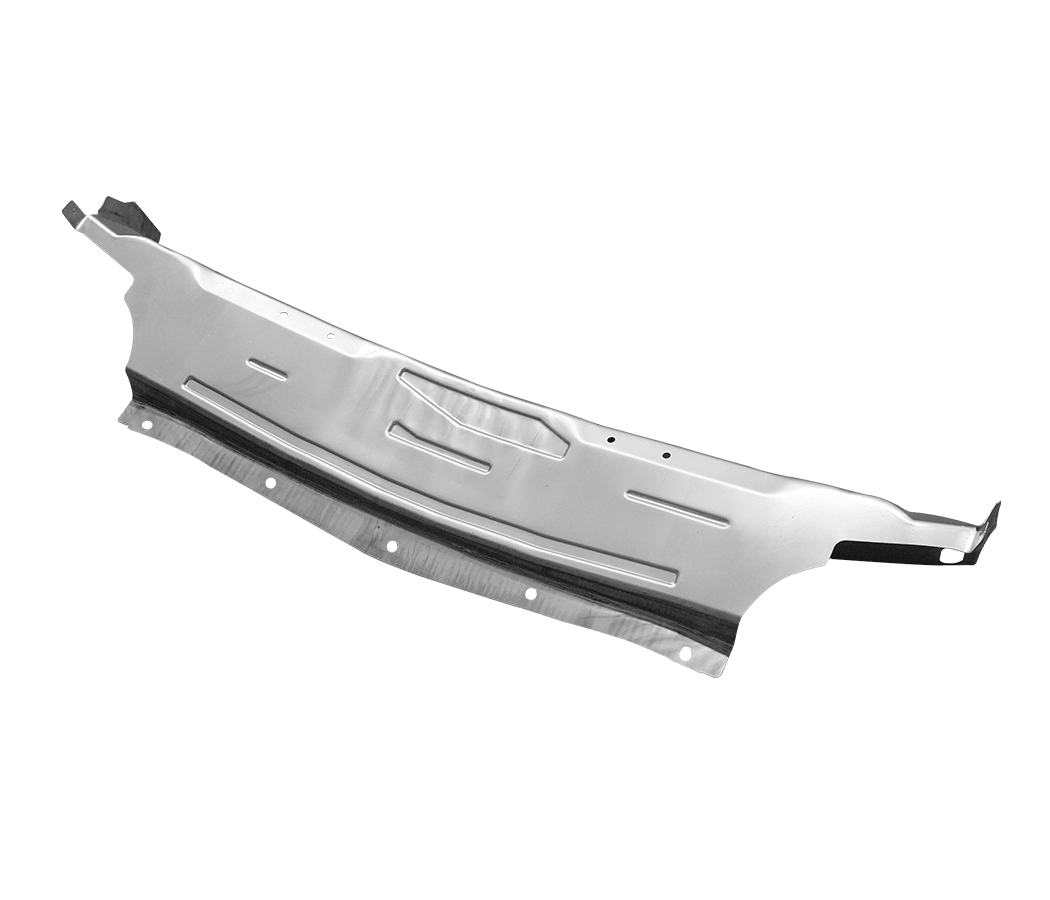

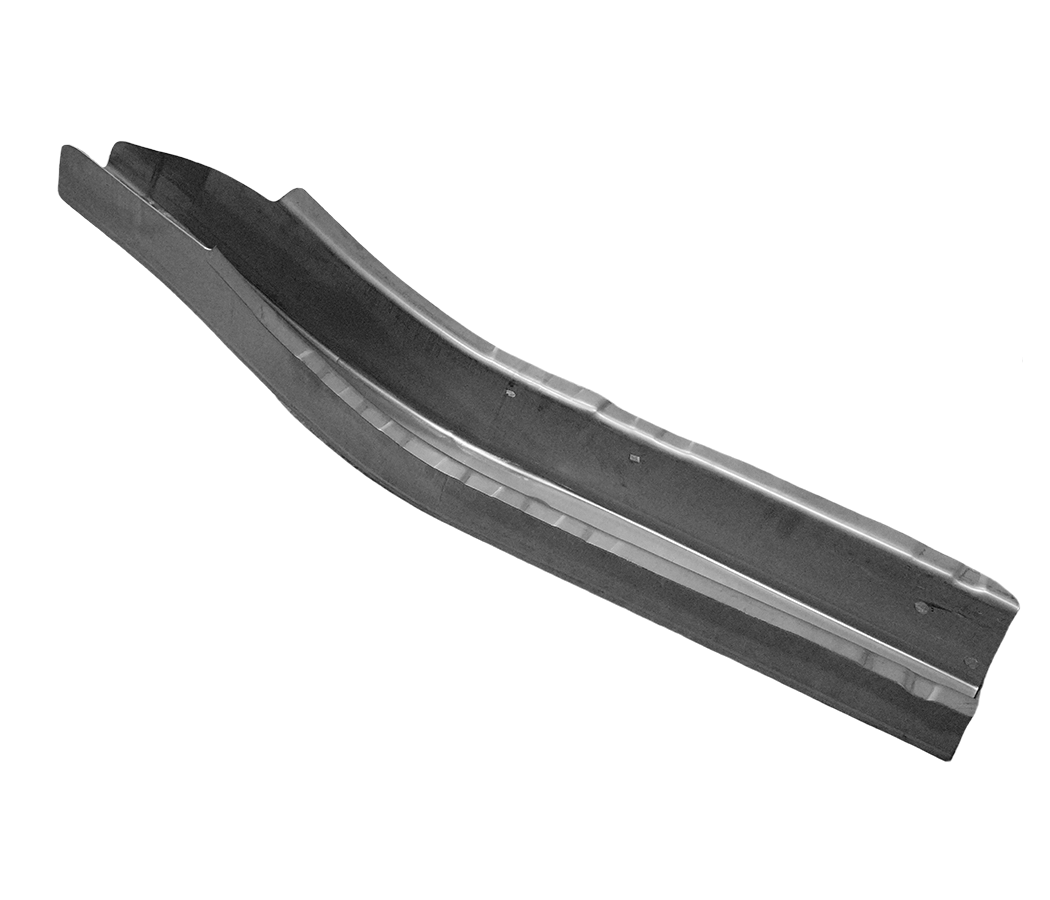

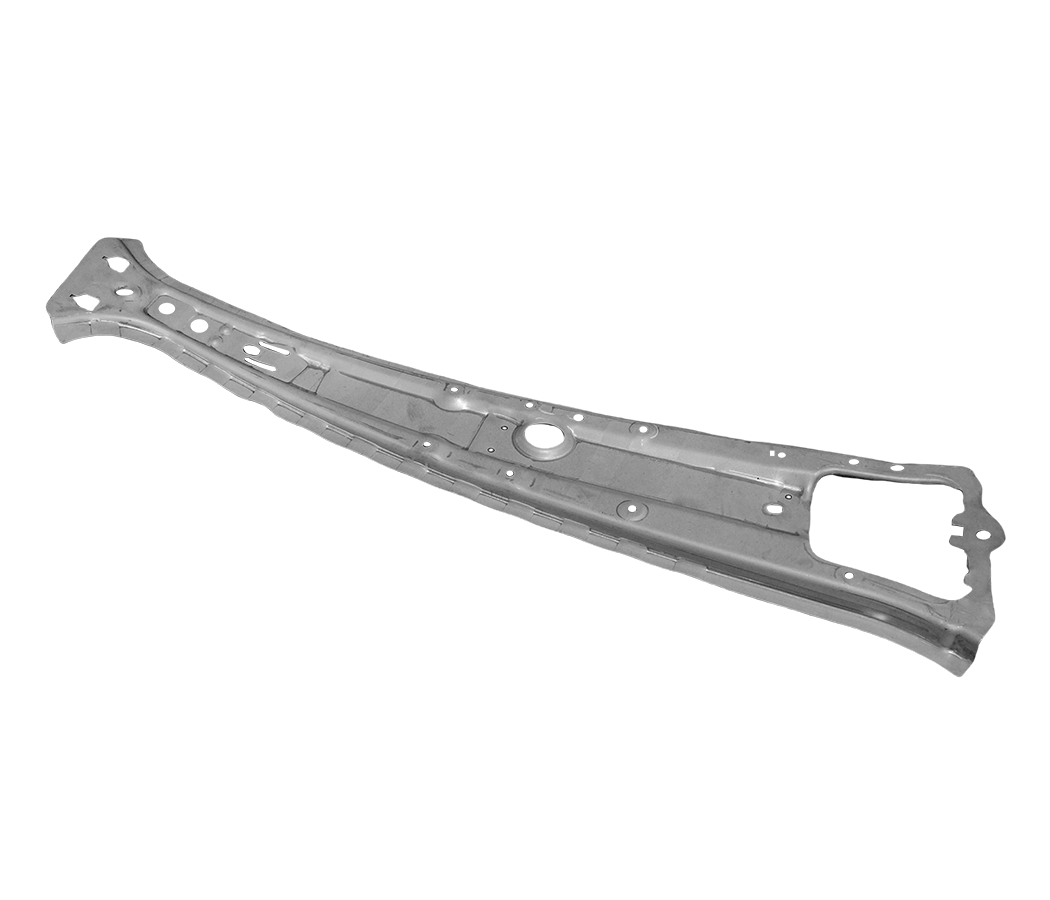

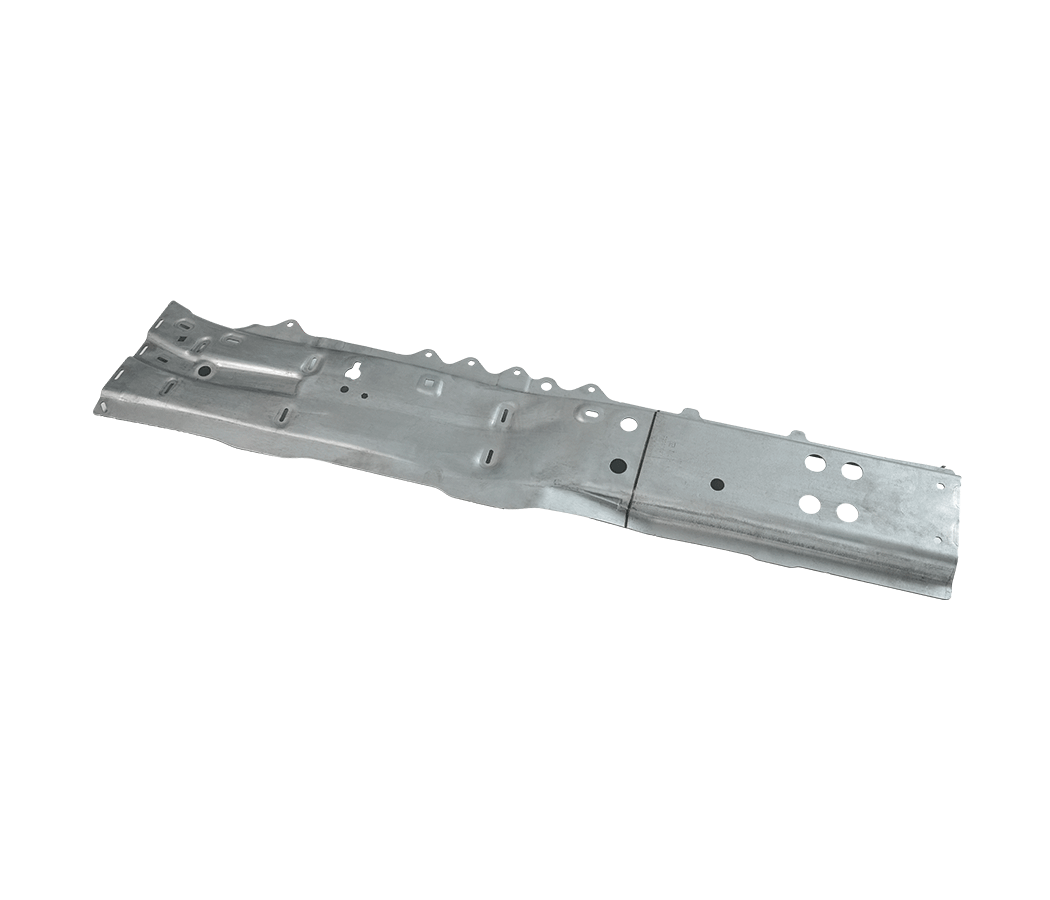

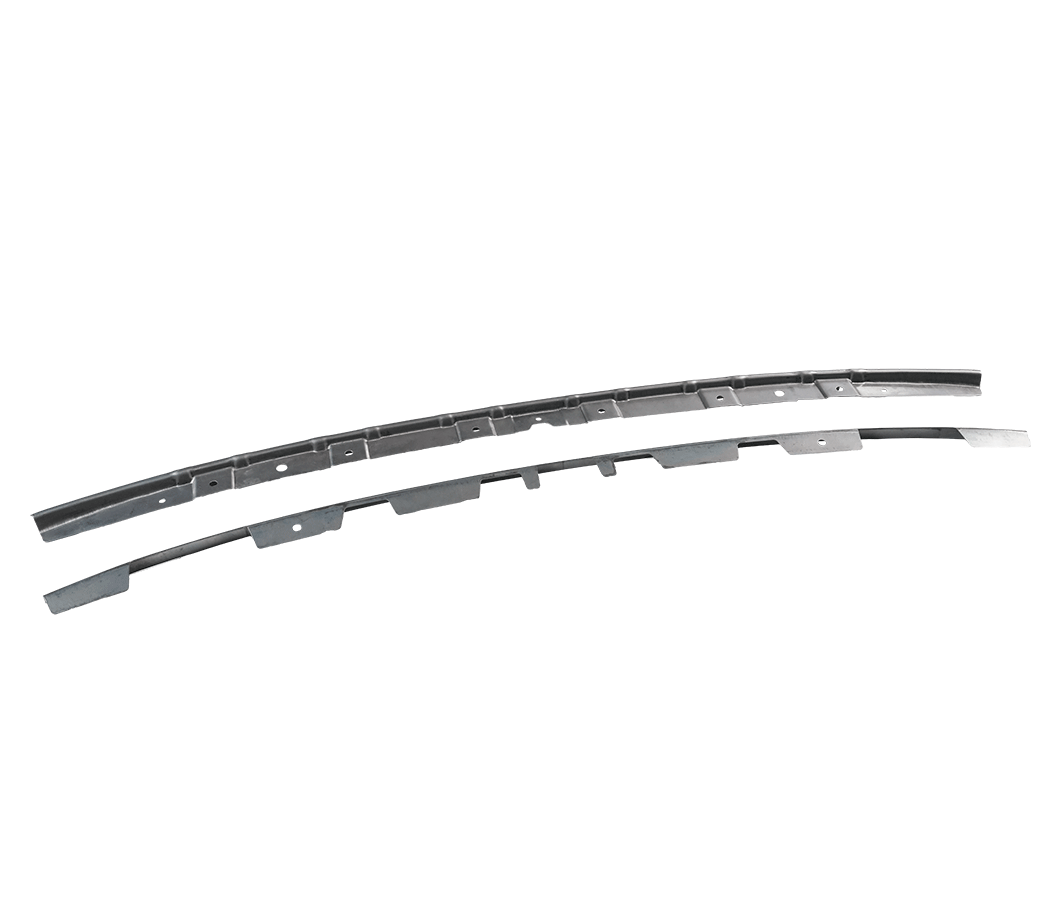

Design and manufacturing of metal stamping tool.

specialized in making progressive tool, transfer die and tandem tool.

-

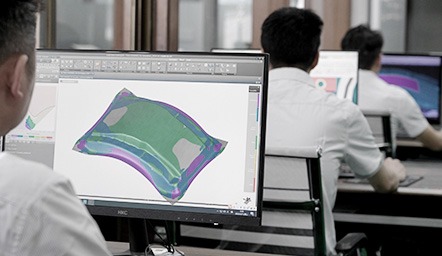

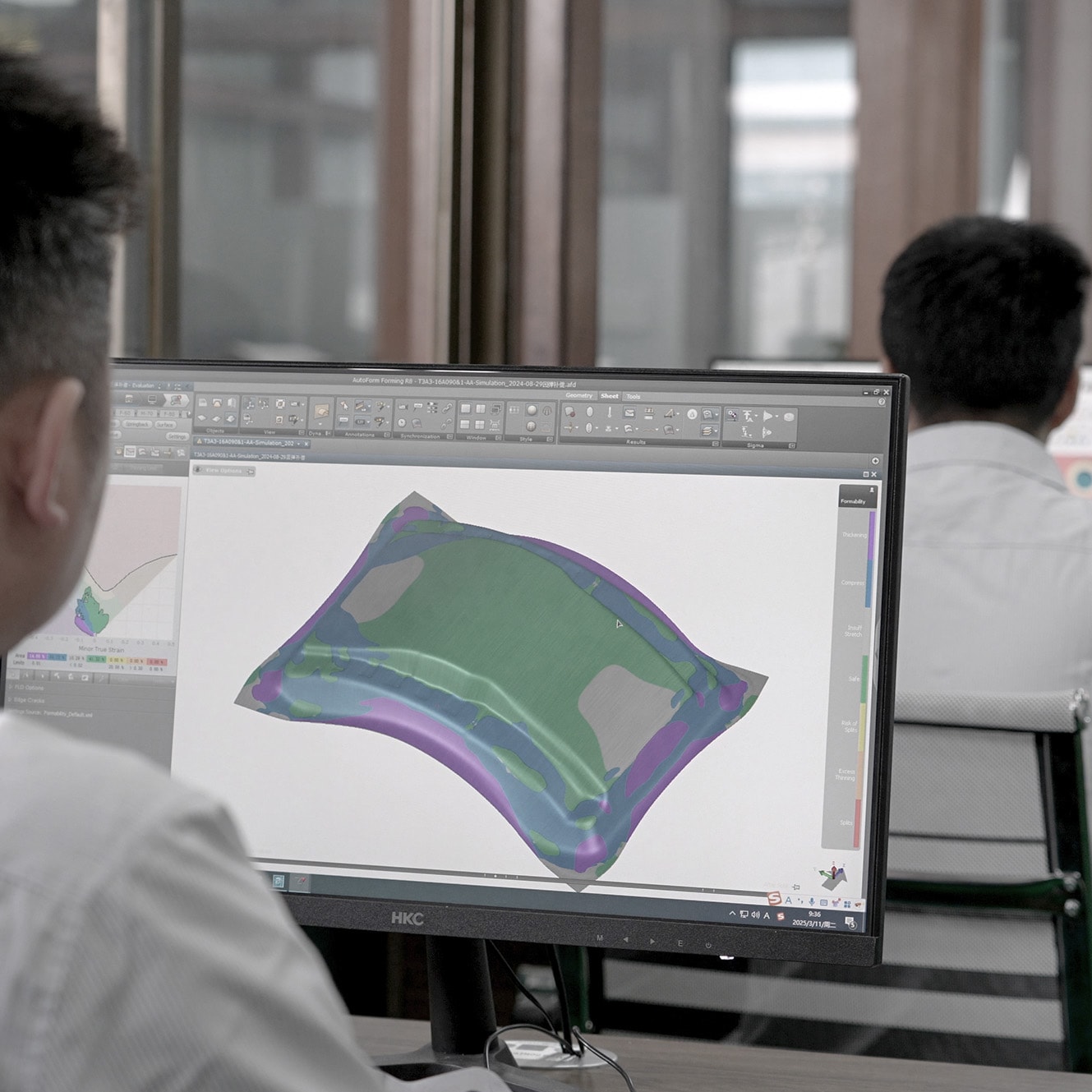

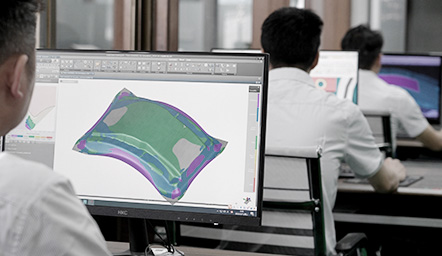

Design Analysis

Design and analysis

-

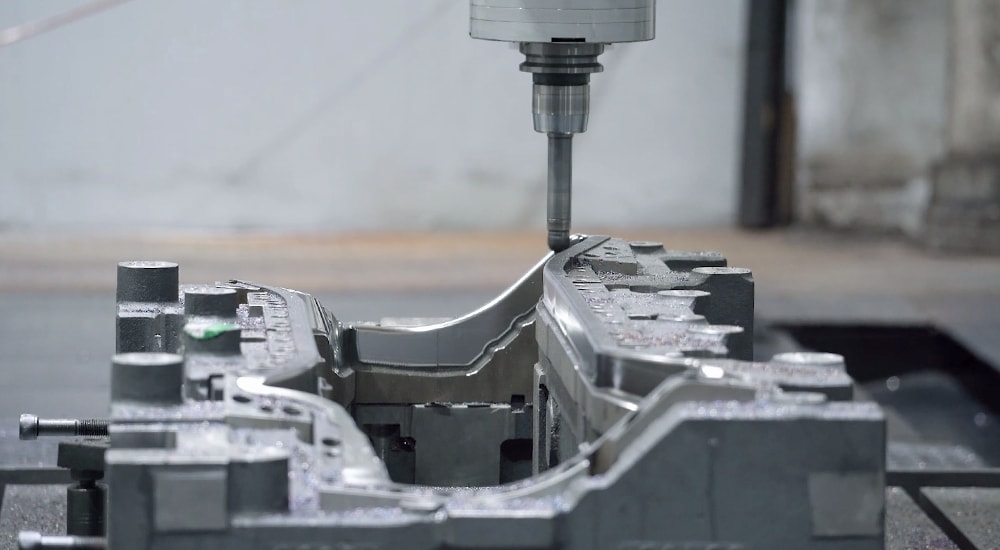

Mould processing

Mould Processing

-

Assembly

Assembly

-

Project Management

Project management

-

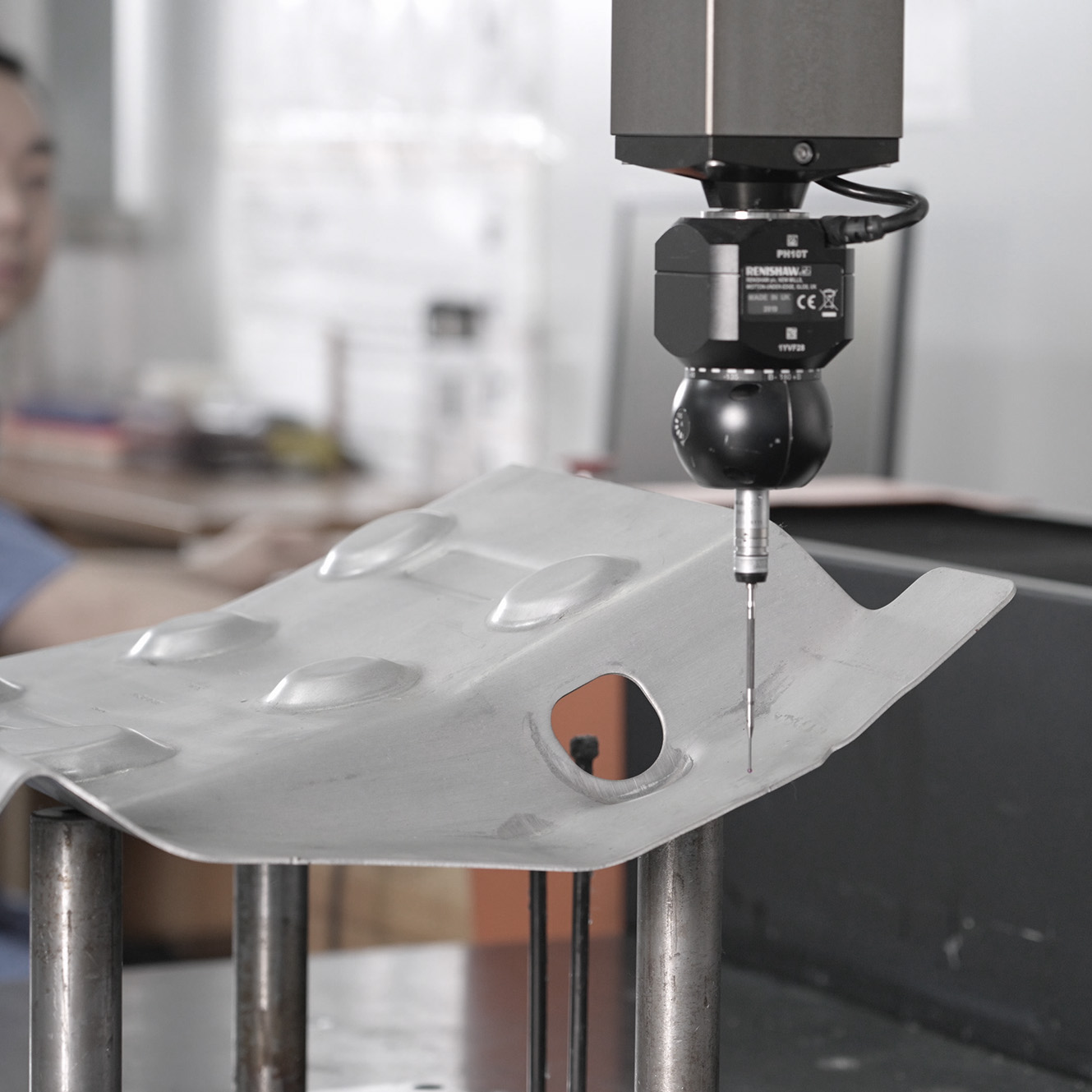

Quality Management

Quality Management